How Are Green Lab-Grown Diamonds Made?

Also known as synthetic or cultured diamonds, lab-grown diamonds are becoming increasingly popular as a sustainable alternative to mined diamonds. Instead of being formed deep beneath the Earth's surface over billions of years, these diamonds are created in a laboratory setting using either the Chemical Vapor Deposition (CVD) method or High-Pressure High Temperature (HPHT) method. Both methods can produce high-quality diamonds, including green lab grown diamonds which are identical to natural ones in terms of chemical composition, physical properties, and optical characteristics.

High Pressure High Temperature (HPHT)

Now let's talk about growing green diamond lab grown. The first method is HPHT. You take a small diamond seed and place it into a press with carbon inside. The press then applies high pressure and temperature to the seed, around 5 gigapascals and 1,500 degrees Celsius respectively. Carbon will then melt and stick to the seed over time, hours or days depending on diamond size.

Chemical Vapor Deposition (CVD)

CVD is a bit newer than HPHT but just as powerful. You put a lab grown green diamond seed in a chamber full of methane gas, then use microwaves or lasers to ionize it until plasma state is reached while having carbon atoms deposit onto diamonds surface layer by layer at low pressures and high temperatures up to about 800 degrees C.

Post-Growth Treatments

The growth process of both HPHT and CVD may produce perfect stones yet they can be further enhanced to look better by undergoing treatments — irradiation or annealing processes that alter their crystal structure while producing desired green hue.

Certification and Grading

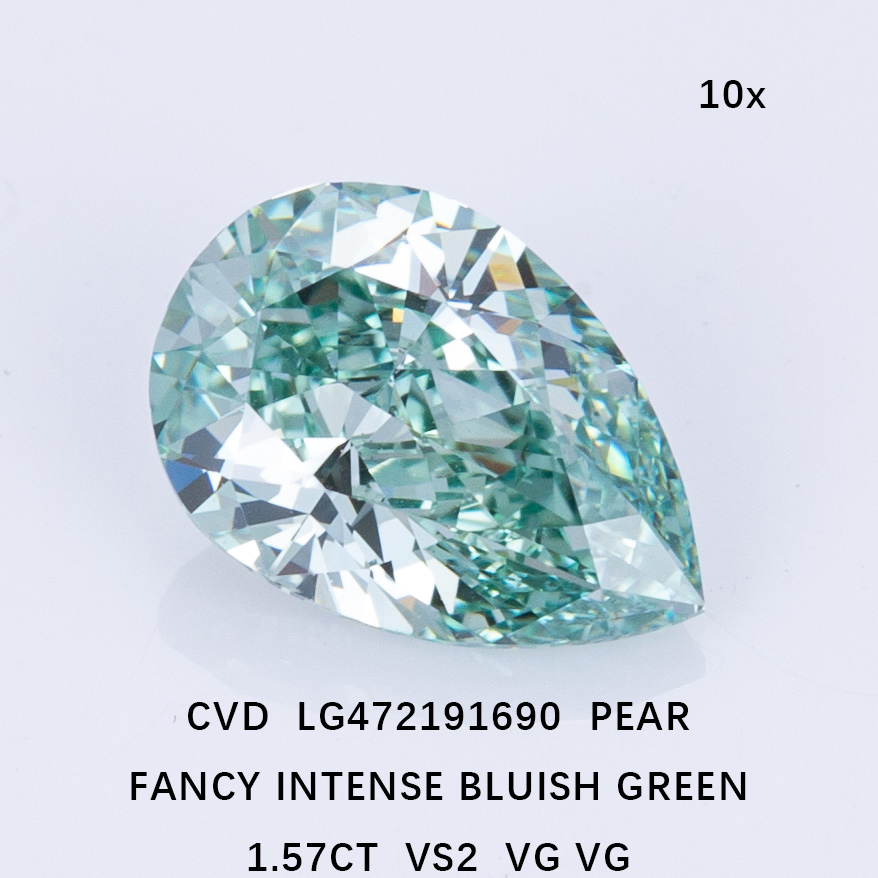

Reputable grading laboratories such as Gemological Institute of America (GIA) and International Gemological Institute (IGI) subject both naturally grown and green lab grown diamonds to stringent grading assessments for authenticity, quality, clarity, transparency, cut before certification.

They use the four ‘Cs’ (cut, color, clarity and carat weight) to grade them. The same criteria are used in grading green lab-grown diamonds so as not to leave any stone unturned.

The Chemical Vapor Deposition (CVD) Process for Green Lab Diamonds

Lab grown green diamonds are complicated to make. To craft these, scientists use a process called Chemical Vapor Deposition (CVD). This process helps them create diamonds that are virtually identical to the ones that we find in mines. They’re chemically, physically, and optically identical. Here’s a quick rundown of how it’s done:

✔First Step: Prep

1. Experts begin by selecting a small piece of diamond seed. This is often just a lab-created diamond and measures about 10x10mm.

2. The seed is then cleaned extensively so that impurities don’t cause defects or inclusions in the growing diamond.

3. Then it's placed inside the growth chamber.

✔Second Step: Growth Chamber

4. Once the seed has been prepped, it must be placed inside the growth chamber.

5. Scientists seal the chamber so no unwanted gases can get through.

6. Then they flood the chamber with carbon-rich gases like methane and hydrogen before heating it up to crazy high temperatures.

✔Third Step: Building Up

7. Although nitrogen could speed things along, many producers skip adding any because it would tint the final color yellowed.

8. The gas mixture falls apart and carbon atoms start to bond onto the diamond seed.

9. Over time, weeks usually, more gas continues to flow into the chamber allowing for more building onto the seed and increasing its size.

✔Fourth Step: After Growth

10. When all is said and done, you’ll have an ugly rough lab green diamond — sorry not sorry! It's an angle cube shape.

11. But! Don't worry, those can still become gorgeous pieces by using traditional polishing techniques paired with laser cutting.

✔Fifth Step: Certification Time

12.Once polished up nicely, this baby needs to be sent out for certification!

13.International Gemological Institute (IGI), among others, will examine the cut, color, clarity, and carat weight to certify its quality.

The High-Pressure High Temperature (HPHT) Diamond Creation Process

The high-pressure, high-temperature method (HPHT) is a technique that tries to replicate the conditions deep inside the Earth. Thankfully, we don't need to be able to dig a really deep hole in order to make lab created green diamond. Here’s a breakdown:

✔Preparing For Greatness

1. We start with a tiny piece of carbon—usually shaped like an already grown diamond—that gets put into a special press.

2. The press squishes carbon under loads of pressure, so much pressure in fact that it mimics the conditions of the Earth's mantle; where natural diamonds are made.

✔Squeezing And Cooking

3. As if being squished isn’t stressful enough, now this poor carbon has to deal with some heat as well! It gets blasted by really hot temperatures from electric currents which helps it grow into something great.

4. With all this bubbling and boiling you’d think something would’ve exploded already! But nope, instead those carbon atoms come together and form their signature crystalline structure.

✔Reaching Maturity

5. Although it takes some time - weeks or even up to a month - This growth process turns our little ‘ole piece of carbon into a rough diamond.

✔Polishing for Style Points

6. Once that part is done, we’re not quite finished yet! We still have to grind down that shapeless rock until it’s an actual diamond fit for jewelry cases everywhere.

7. To do this we use fancy laser cutters as well as traditional polishing methods used on other gemstones.

✔Making It Official

8. Finally! Our shiny new HPHT diamond is ready for its check-up!

9. Certified experts look over every inch of the thing to verify its cut, color, clarity, and weight so they can prove its quality and confirm its origins as an HPHT lab grown green diamond through institutions like the International Gemological Institute (IGI).

Conclusion

The green lab diamond origin are created by advanced technological processes which mirror the natural formation of diamonds. Both HPHT and CVD methods can produce high-quality synthetic green diamond, which are then treated after growth to reach the desired color.

These provide a sustainable and preferred option for consumers – combining the timeless beauty of lab created green diamonds with environmental responsibility and social values.

Contact Us

Tel.: +86 15878079646

Email: info@messijewelry.com

WhatsApp:+86 15878079646

Company Address: Room B5, B6, B7, B8, Building 2, No. 137, Xinxing 2nd Road, Wuzhou, GuangXi, China.

One of the experienced lab grown diamond manufacturers, Messi Jewelry is always working for your satisfaction, welcome to negotiate business cooperation with us.